Repairs to Mercedes carbon fiber parts demand stringent adherence to OEM standards for quality and precision, utilizing approved materials and techniques to maintain structural integrity and aesthetic appeal. Skilled technicians perform meticulous assessments, use advanced tools, and apply expert craftsmanship to restore components to like-new condition, ensuring both functional and visual excellence in Mercedes carbon fiber parts repair.

In the realm of luxury automotive restoration, maintaining OEM (Original Equipment Manufacturer) standards is paramount for ensuring both quality and aesthetics. When it comes to repairing Mercedes carbon fiber parts, a meticulous process is required to match the precision and durability of the original materials. This article delves into the intricacies of understanding OEM standards, outlining the step-by-step Mercedes carbon fiber repair process, and highlighting techniques to achieve longevity and impeccable visual appeal in carbon fiber restoration for these high-end vehicles.

- Understanding OEM Standards for Quality Assurance

- The Mercedes Carbon Fiber Repair Process Step-by-Step

- Ensuring Longevity and Aesthetics in Carbon Fiber Restoration

Understanding OEM Standards for Quality Assurance

Understanding OEM Standards for Quality Assurance is paramount when dealing with Mercedes carbon fiber parts repair. These standards, set by the Original Equipment Manufacturer (OEM), ensure that repairs maintain the same level of precision, quality, and durability as the original vehicle components. For Mercedes vehicles known for their luxury and advanced materials like carbon fiber, adhering to OEM guidelines is crucial. This involves using specific adhesives, resins, and techniques approved by Mercedes to preserve the aesthetic and structural integrity of the car.

When carrying out auto body repairs on Mercedes vehicles with carbon fiber panels, technicians must be well-versed in not just vehicle dent repair but also the unique challenges posed by this advanced material. Proper training and certification are essential to guarantee that repairs meet OEM standards. This includes understanding how to handle complex shapes, intricate designs, and the specific properties of carbon fiber to prevent damage or degradation during the repair process. The goal is always to ensure that the repaired area not only looks like new but also functions as effectively as the original Mercedes carbon fiber parts.

The Mercedes Carbon Fiber Repair Process Step-by-Step

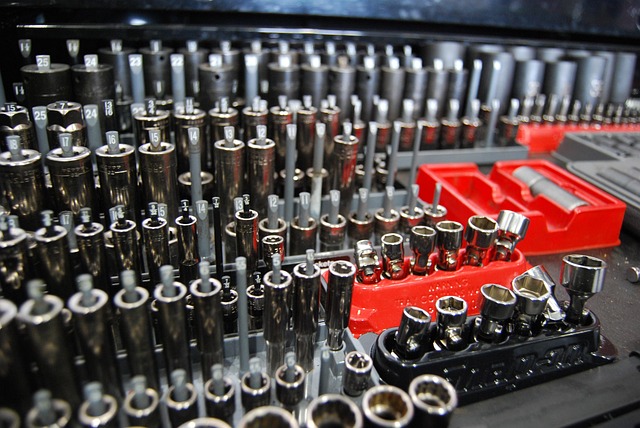

The Mercedes Carbon Fiber Repair Process is a meticulous art that requires precision and an understanding of advanced materials. It begins with assessing the damaged part, identifying the extent of repair needed, and preparing the carbon fiber composite material. Skilled technicians use specialized tools to clean and decontaminate the surface, ensuring no debris or contaminants interfere with adhesion.

Next, a primer is applied to activate the carbon fiber’s surface, enhancing bond strength. The repair then involves carefully matching and molding new carbon fiber sections to fit seamlessly with the existing structure. After curing, the repaired area undergoes rigorous testing for quality assurance, including pressure tests and visual inspections. This meticulous process guarantees that Mercedes carbon fiber parts maintain their superior performance, aesthetics, and structural integrity, mirroring the precision of original equipment manufacturing (OEM) standards.

Ensuring Longevity and Aesthetics in Carbon Fiber Restoration

In the intricate world of Mercedes carbon fiber parts repair, achieving both longevity and aesthetics is paramount. Skilled technicians employ precise techniques to restore these lightweight yet durable components, ensuring they meet OEM (Original Equipment Manufacturer) standards. This meticulous process involves careful inspection, accurate measurement, and expert craftsmanship to match the exact specifications of the vehicle.

The goal is not just to fix, but to revive the carbon fiber’s original condition, maintaining its sleek appearance and structural integrity. Advanced tools and specialized coatings are utilized to fill in defects, smoothen surfaces, and enhance the material’s natural resilience against environmental factors. This meticulous attention to detail translates into a superior vehicle repair experience, leaving customers with not just functional, but visually stunning Mercedes carbon fiber components that rival the original factory finish.

In conclusion, adhering to Original Equipment Manufacturer (OEM) standards is paramount for ensuring high-quality Mercedes carbon fiber part repairs. By meticulously following a structured process, from understanding material properties to precise restoration techniques, technicians can achieve not only exceptional durability but also maintain the aesthetic appeal that defines Mercedes vehicles. This attention to detail is key in preserving the vehicle’s value and performance for years to come, making professional carbon fiber repair services an invaluable asset for any Mercedes owner.